Modern 3D printing technologies, e.g., DLP printers, are emerging, especially with the growth of 3D printing across key industries. DLP 3D printers have exceptional 3D printing capabilities. That’s why they are popularly used in industries like dentistry and jewelry.

This article is designed to help you understand everything about DLP printers. You are going to learn the following:

- How a DLP 3D printer works and the type of 3D printing materials it uses

- Benefits and demerits of using a DLP resin printer

- Finally, the applications of a DLP printer

We’ll also provide tips to help you understand how to utilize this printer’s features.

Let’s get started!

What is a DLP Printer?

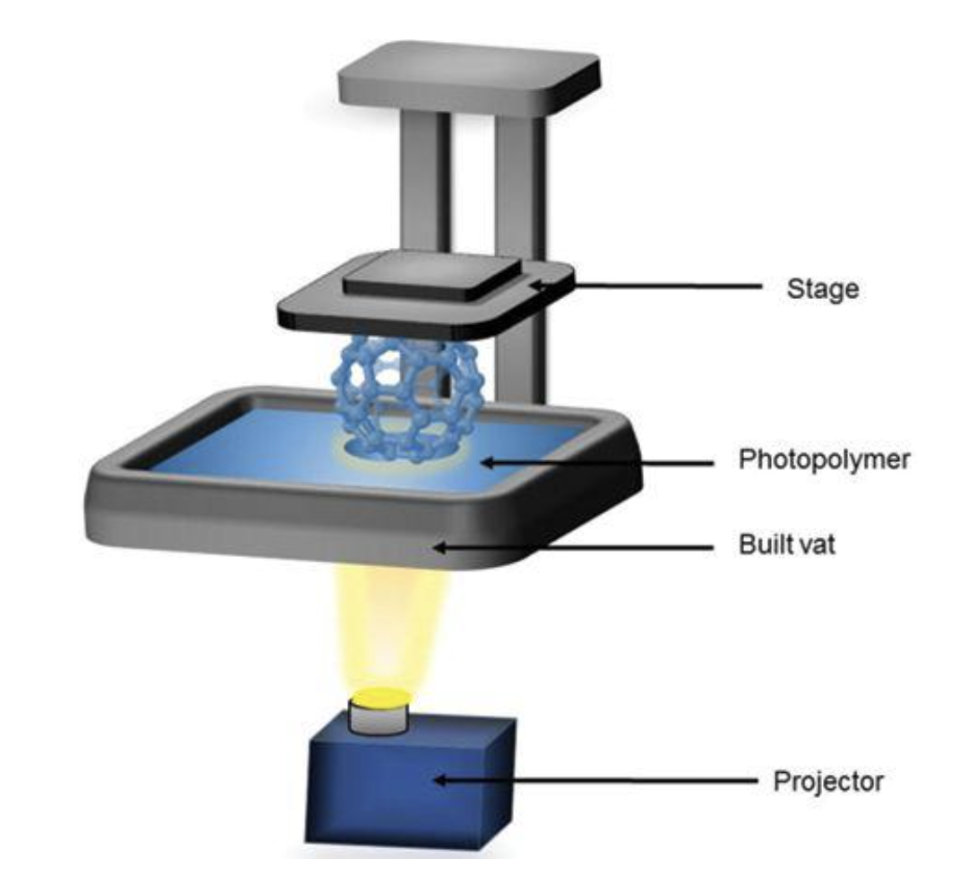

A DLP printer is one of the newer 3D printing machines that use photosensitive resins to print aesthetic 3D models. A DLP 3D printer uses a digital light processing projector to shine light on a photosensitive resin in a pattern that will enable you to print your 3D model.

The resin then solidifies after being exposed to the projector’s light. It is essential to note that DLP printers use 3D resin as their primary 3D printing material. Please specify which resin printer you use.

Doing so will help you avoid wasting time and possibly losing your hard-earned money.

Which Popular 3D Printing Materials Does a DLP 3D Printer Use?

A DLP 3D printer uses liquid photosensitive resin (photopolymer) to print highly detailed 3D models. Check out some of the most popular DLP printer resins:

- Standard resin – this DLP 3D printing material is popular because of its tensile strength and versatility. This resin is ideal for rapid prototyping because of its stability and dimensional accuracy. It also cures quickly.

Unfortunately, you can only use standard resin to print visual models. This printing material is brittle, meaning it is not entirely impact-resistant.

- Dental resin – as its name suggests, this DLP printer resin is mainly used in the dental industry. It can be used to print custom biocompatible oral cavities. Dental resins are further utilized to print surgical guides.

Like the standard resin, dental resin is also popular because of its stability, low shrinkage & failure rates, and excellent dimensional accuracy.

- Castable resin – This DLP printer resin is pretty versatile. It can be used to print castable dental models or castable jewelry. This 3D printer resin is popular because it prints smooth and uniform 3D models.

Despite being more expensive than other DLP resins, castable resin offers an economical way of printing small 3D models that are highly detailed.

Warning: We strongly recommend printing 3D models using these resins in a well-ventilated environment. Inhaling the fumes produced by these photopolymers during printing is dangerous to your health.

Short-term effects may include dizziness, irritation to the nose, throat, lungs, etc. The most deadly long-term effect is the increased risk of getting cancer.

After you no longer have use for your printed 3D model, consider getting rid of it in an environmentally responsible way. Failure to do that could cause environmental damage, i.e., pollution.

What are the Benefits of Using a DLP 3D Printer?

DLP printers are continually becoming popular because of the following reasons:

- Rapid printing – a DLP printer takes the lead in printing speed compared to its competitor, the SLA 3D resin printer. A DLP printer cures an entire layer of the photosensitive resin in one go using its intense light.

- Smooth surface finish with great details – DLP printers can print models with uniform and smooth surfaces.

- Easy post-processing – It is essential to ensure that the printer’s settings are ideal for printing the type of model you want. After printing your 3D model using a DLP 3D printer, you can be sure that post-processing will be quick and easy.

- Accuracy – DLP 3D printers can print highly accurate 3D models with intricate designs, especially when using high-end 3D DLP printer resin.

- A DLP 3D printer has lower maintenance costs than other 3D resin printers, e.g., LCD 3D resin printers.

- Its shallow resin tank is a minor but noteworthy advantage of using this type of printer. A shallow tank will help you reduce resin wastage, making your 3D printing process efficient.

What are the Downsides of Using a DLP Printer?

Having stated the core benefits of using this type of 3D printer, it is also essential to take note of its downsides. There are two core downsides to using a DLP printer:

- DLP 3D printers are ideal for printing small 3D models. You need to be aware of the risk of warping, especially when printing bigger 3D models.

- Low-end DLP printers are less accurate than their high-end counterparts. It is more beneficial to acquire LCD 3D resin printers, especially if you want to print highly detailed 3D models on a budget.

Where are DLP 3D Printers Used? (DLP 3D Printer Applications)

DLP 3D printers are popularly used in the following industries:

- Dental labs – You read earlier in this article that dental resin is one of the most popular DLP printer resins. Dental labs utilize accuracy and rapid printing to print custom oral cavities for their patients.

- Jewelry shops – Castable resin is used to make jewelry. Jewelry makers can utilize the DLP 3D printer’s high accuracy to print jewelry models. They can also benefit by using a DLP printer because it prints models that have smooth and uniform surfaces.

Pro tip: It would be best for jewelry shops to use high-end DLP 3D printers as they produce more detailed 3D models.

- Healthcare industry – DLP printers are popularly used to print small devices such as hearing aids. You can use this printer to print custom hearing aids to fit a patient’s unique needs. The best part of it all is how DLP 3D printing has made the process fast and economical.

Pro tip: When printing 3D models with complex angles, consider using support material. It will enable you to print better 3D models by ensuring that the models do not deform.

Wrap-up on DLP 3D Printers

What can you print using a DLP 3D printer?

You can print almost anything using a DLP 3D printer. However, ensuring that you are using the correct 3D resin and that your printer’s settings match the selected resin is essential. Doing so will guarantee you the production of high-quality 3D models that are highly detailed.

Remember, DLP 3D printers are ideal for printing small 3D models. Printing large models increases the risk of warping.

You may be interested in: What to look for in a 3D printing service