For various industrial and manufacturing processes, compressed air is important. It is used in fuel combustion applications, pneumatic tools, filtration systems, metalworking, and many more.

For all these tasks, air movement should be free from the dust particles and other particle matter that might get mixed with air. To facilitate the process, air compressors are fitted with a filter mechanism that will prevent dust particles and other matter from passing through the compressor.

Filters play a crucial role in eliminating the particle content to get mixed up with the compressed air. The filtration system thus requires regular maintenance and the parts present in it should be replaced frequently so that the entire system runs smoothly and efficiently.

Today, we will learn about an air compressor filter and the benefits of changing it frequently for the optimal functioning of the system.

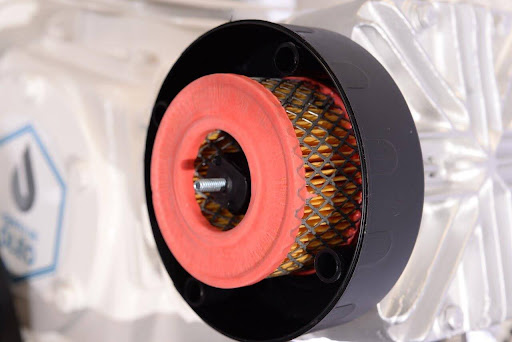

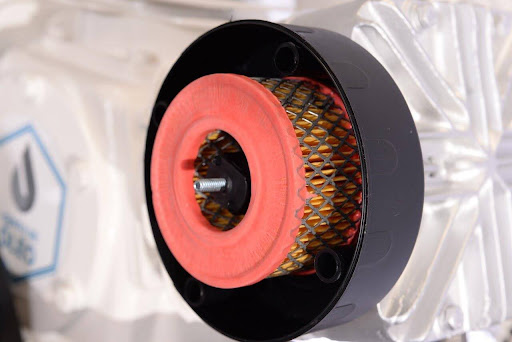

Let’s see what the compressed filter consists of before we move on to the benefits. They have filters like coalescing filters, dry particulate filters or a combination of both. The first is used to pull oil and water droplets from the air thus cleaning the air from any liquid contaminants.

The latter is used to capture the particle matter such as dust particles and microbes. They both have a removed filter element called a cartridge. You can take it out, clean it thoroughly and put it back for the better functioning of the system.

The filter elements should be tolerant to harsh industrial conditions like pressure fluctuations, extreme temperatures, varying air speeds, corrosive chemicals and extreme humidity variation. The filters and their elements are designed in such a way that they can be used in any industrial setting without any issues.

When working continuously in a harsh environment, the filters will lose their working capacity and cause degradation. It will not let the filters filter the contaminants properly affecting the whole process in the manufacturing or industrial unit.

That is why you should know the importance of cleaning filters and understand why they need to be changed periodically.

Benefits of replacing filters regularly:

Filters do a splendid job of keeping the air clean and neat in the working environment. All the workers and other employees who constantly work in this environment will not be subjected to poor air quality. They are protected from unwanted contaminants that might cause harm or discomfort while working.

Using filters will prevent the workers from facing undesirable conditions like poor air quality, overheating equipment and system malfunctions. All these conditions can adversely impact the health condition of workers and can cause them to quit or take leave for a longer duration. It will not only affect the productivity but also you can get a bad name.

Hence changing the filters at regular intervals is important to maintain a safe and clean environment.

The regular changing of filters will decrease the risk of system problems like inefficiency, costly repairs, and downtime. Without proper filter maintenance, the filters won’t work properly and the whole compressor system has to work harder to get adequate flow.

The excessive pressure on the compressor will increase the load on it and cause excess wear. It also leads to high energy usage and the whole system can be affected due to the improper functioning of the system.

All the increased load will lead to a rise in operational costs and decrease in the service life of a compressor. Hence you should change the filters frequently so that the whole system works optimally.

When the filters are clean, the compressed air flows without any obstructions. The unobstructed flow of filtered air will allow the working mechanism to work smoothly without any issues. It increases productivity and you can see a rise in your profits because of the regular maintenance of air filters. If not, you can look for the signs of improper working of air filters and get them changed as soon as possible.

Changing filters is a simple task yet it gives you an immense sense of peace. As it allows the whole system to run at its high efficiency and productivity, you can sit back and relax knowing that the system is working properly. It will make your employees enjoy a safe and cleaner environment.

What happens when filters are not changed frequently?

When filters are contaminated and the compressed air is not flowing freely through them, you can expect to see:

- Inefficiency in the production

- Damage to system components

- Increased downtime

- Unhealthy work environment

- Product and process contamination

- Consumer safety risk

Conclusion

For any industry to work properly in the manufacturing process, all systems should work properly including the air filtration system. Ensuring proper maintenance and changing the filters periodically will keep the system up and running without any issues. The simple task of looking at the damaged filters and replacing them will save you thousands of dollars and increase productivity.

Author Bio:

Hi, I am Mike Morleye. As a professional writer, I put together my writing skills to share knowledge on diverse topics in a readable, understandable and appealing format. Follow me back on Facebook, Twitter and LinkedIn.

Interesting Related Article: “Air Conditioning Maintenance in Rental Properties: Landlord or Tenant Responsibility?“

![[CHAINALYSIS PODCAST EPISODE 52] Reshaping the NFT Ecosystem in the Wake of the 2022 NFT Market Crash and Crypto Storm [CHAINALYSIS PODCAST EPISODE 52] Reshaping the NFT Ecosystem in the Wake of the 2022 NFT Market Crash and Crypto Storm](https://blog.chainalysis.com/wp-content/uploads/2023/04/Episode-52-Website-Graphic.png)