The world of botanical extraction has come a long way, with new technologies and techniques being developed to produce high-quality extracts from plants. In this extensive guide, we dive deep into the fascinating world of botanical extraction equipment, exploring the latest innovations and methods used to obtain the valuable compounds from plants. So, buckle up and join us on this exciting journey through the cutting-edge world of botanical extraction.

Defining Botanical Extraction Equipment

Botanical extraction equipment refers to a range of specialized machinery and tools designed to extract valuable compounds, such as essential oils, flavonoids, and cannabinoids, from plant materials. These machines use various methods, including solvent-based extraction, mechanical pressing, and supercritical CO2 extraction, to isolate the desired compounds from the plant matrix. The extracted compounds are then used in a wide array of applications, from pharmaceuticals and cosmetics to food and beverage production.

Types of Botanical Extraction Equipment

Different types of botanical extraction equipment serve specific purposes, each utilizing a unique extraction method to obtain the desired compounds from plant materials. In this section, we will discuss some of the most popular types of extraction equipment and the techniques they employ.

Solvent-Based Extraction Equipment

Solvent-based extraction equipment uses chemical solvents, such as ethanol, butane, or hexane, to dissolve the desired compounds from the plant material. This process usually involves soaking the plant material in the solvent, followed by evaporating the solvent to leave behind the extracted compounds. Common solvent-based extraction equipment includes:

Closed-loop extraction systems: These systems are designed for hydrocarbon extraction, such as butane or propane, and are considered safer than open-loop systems as they minimize the risk of solvent exposure and explosions.

Rotary evaporators: These devices are used to separate solvents from the extracted compounds by applying heat and vacuum pressure, resulting in a highly concentrated extract.

Mechanical Pressing Equipment

Mechanical pressing equipment relies on physical force to extract essential oils and other compounds from plant materials. This method is often used for extracting oils from seeds, nuts, and fruits. Examples of mechanical pressing equipment include:

Cold press machines: These machines use a hydraulic press to apply high pressure on the plant material, releasing the essential oils without the need for heat or solvents.

Expeller presses: Expeller presses use a screw mechanism to apply continuous pressure on the plant material, forcing the oils out through a small opening.

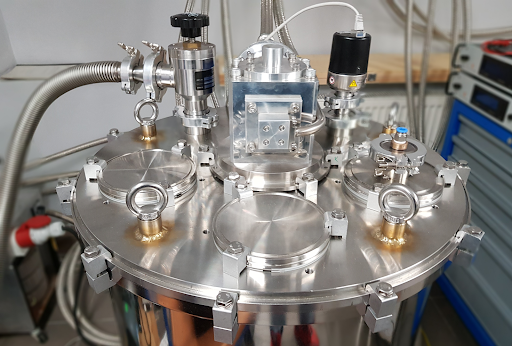

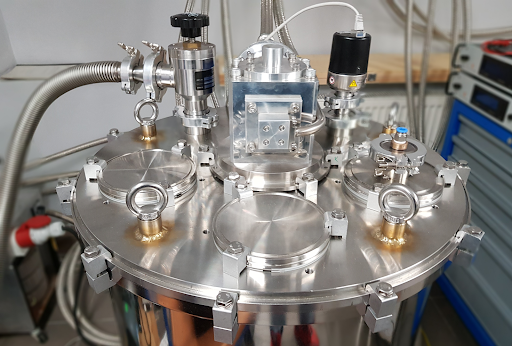

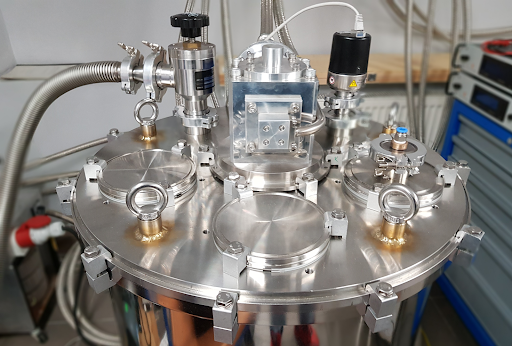

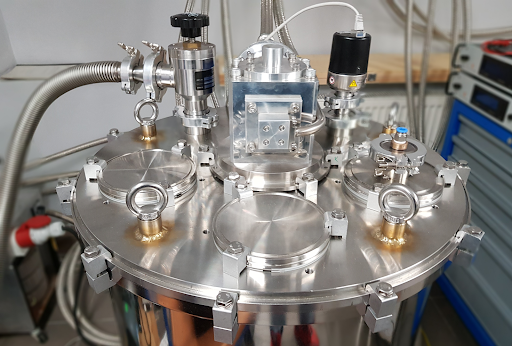

Supercritical CO2 Extraction Equipment

Supercritical CO2 extraction equipment utilizes carbon dioxide in a supercritical state (a state where CO2 exhibits properties of both a liquid and a gas) to extract the desired compounds from plant materials. This method is known for its high efficiency, selectivity, and environmentally-friendly nature. Supercritical CO2 extraction equipment includes:

CO2 extraction systems: These systems consist of a series of high-pressure vessels, pumps, and heat exchangers designed to manipulate CO2’s temperature and pressure conditions, allowing it to penetrate the plant material and dissolve the desired compounds.

Factors to Consider When Choosing Botanical Extraction Equipment

Selecting the right extraction equipment for your needs is crucial for obtaining high-quality extracts. Here are some factors to consider when making your decision:

Type of plant material: Different extraction methods work best for different types of plant materials. For example, solvent-based extraction is more suitable for extracting cannabinoids. For the extraction process it is used a cannabis extraction system, while mechanical pressing is ideal for obtaining oils from seeds and nuts.

Desired compounds: The type of compounds you wish to extract will influence your choice of extraction equipment. Supercritical CO2 extraction, for instance, is highly selective and can target specific compounds, while solvent-based extraction may result in a broader spectrum of compounds being extracted.

Quality of the final product: The extraction method used can significantly impact the quality of the final product. For example, cold press machines are known for producing high-quality essential oils, while solvent-based extraction may leave behind traces of solvent in the extract, which may require further purification.

Production scale: Your intended production scale should also influence your choice of extraction equipment. Some methods, like supercritical CO2 extraction, are more suitable for large-scale production, while mechanical pressing may be more appropriate for smaller-scale operations.

Budget: The cost of the extraction equipment can vary significantly depending on the method, features, and capacity. Consider your budget when selecting the right equipment for your needs.

Advantages of Using Botanical Extraction Equipment

Investing in specialized botanical extraction equipment offers several advantages:

Improved efficiency: Modern extraction equipment is designed to optimize the extraction process, resulting in higher yields and shorter extraction times.

Enhanced safety: Advanced safety features in extraction equipment minimize the risks associated with handling hazardous solvents or high-pressure systems.

Consistent quality: Using specialized extraction equipment ensures the consistency and quality of the final product by maintaining optimal extraction conditions and reducing the chances of contamination.

Scalability: Extraction equipment is available in various sizes and capacities, allowing businesses to scale up or down their production as needed.

Environmental sustainability: Some extraction methods, such as supercritical CO2 extraction, are more environmentally friendly than traditional solvent-based methods, reducing the environmental impact of the extraction process.

Proper Maintenance and Cleaning of Botanical Extraction Equipment

To ensure the longevity and efficiency of your extraction equipment, proper maintenance and cleaning are essential. Some best practices include:

Regularly inspecting the equipment for wear, leaks, or damage and addressing any issues promptly.

Cleaning and sanitizing the equipment according to the manufacturer’s recommendations to prevent the buildup of residues and contaminants.

Replacing worn or damaged parts as needed to maintain optimal performance.

Scheduling routine maintenance checks with a qualified technician to ensure the equipment is functioning correctly and safely.

Conclusion

Botanical extraction equipment plays a vital role in obtaining valuable compounds from plant materials for various applications. Understanding the different types of extraction equipment, their advantages, and factors to consider when choosing the right equipment for your needs is essential for achieving optimal extraction results. By investing in specialized extraction equipment and following proper maintenance and cleaning practices, you can ensure the efficiency, safety, and quality of your extraction process.

Interesting Related Article: “The Essential Guide To White Label Product Manufacturing“