With the advancement of software designs and production technologies, engineers can manufacture PCBs that are small, complex, and multilayered more reliably and efficiently than in the past. These modern PCBs have very little resemblance to their old designs. In the past, the most costly technologies like HDI, microvias, and rigid-flex were only available to the fancy designers but now just after ten years, they are readily available to all the designers everywhere.

As we move towards 2024, with each passing year the demand for technology and customer service grows, and the trends in PCB manufacturing will also change. PCBs are used in all types of electronic and digital devices, and with the technological advancement of these devices, PCB manufacturers feel intense pressure to find new ways to develop PCBs. Now that customers want flexible and thinner PCBs and businesses want better functionality, the manufacturers should keep evolving and reshaping PCB board manufacturing. With increasing challenges and complexities there will always be room for the development of PCBs.

This article will particularly focus on the top trends in reshaping the PCB manufacturing process in 2024. Now let’s have a look at what manufacturing trends the manufacturers will be focusing on in the coming year.

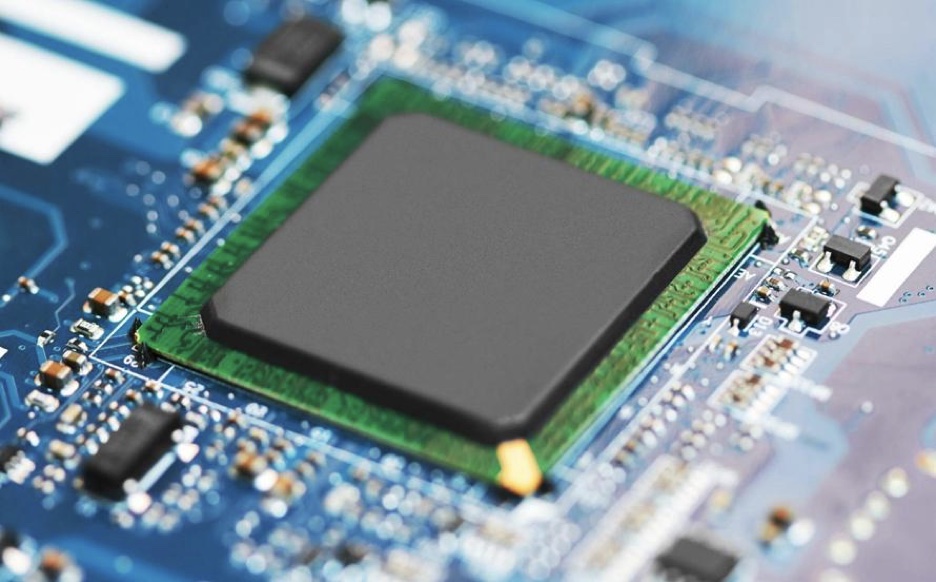

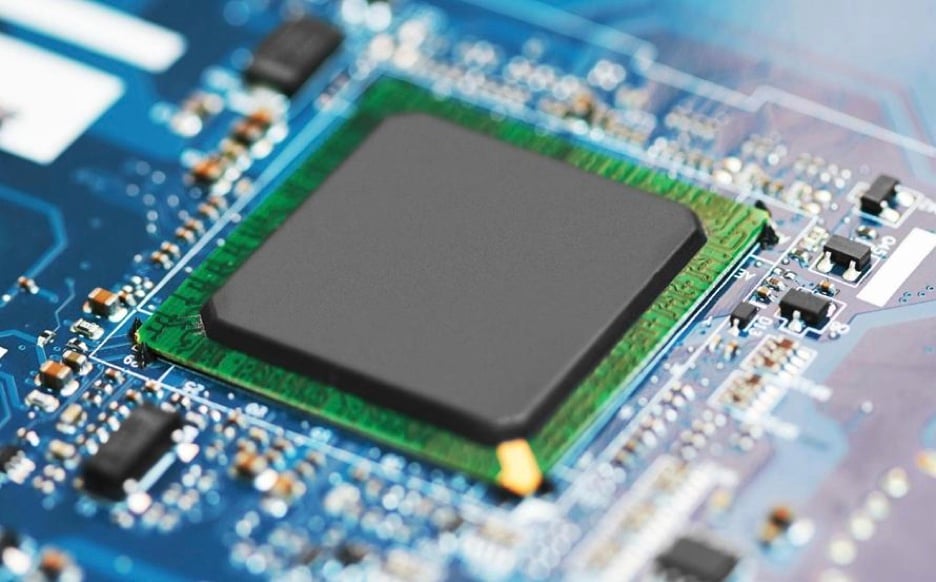

Miniaturization of PCB Boards

Recently, PCB manufacturers have been focused on the miniaturization of PCB board manufacturing with the advent of new materials and technologies. One example is the micro-camera. Micro-cameras are tiny cameras that are used to take high-resolution images and videos with quality and durability. This is a growing trend in 2024. Unlike normal cameras, micro-cameras have different parts like lenses, holes, and sensors that help to take high-quality images and videos. These cameras are directly attached to the boards of circuits and they can fit any size of the PCB.

Micro-cameras have a broad set of applications and are readily used in electronic PCB manufacturing, medical instruments, and surveillance technology.

Consumer electronics

The PCB manufacturers would work to improve the quality of the cameras as companies are now demanding complex and tiny cameras that could fit their electronic devices. These cameras are readily used on mobile phones, laptops, and even tablets.

Medical instruments

In today’s world healthcare sector takes the lead in using micro-camera which does not need to undergo surgery. The patient can swallow the camera and the doctor can examine without invasive process. These cameras are pill-sized and also wearable during the surgery.

Surveillance technology

Surveillance cameras are used by companies, consumers, and different organizations to monitor their homes and other unexpected guests. As micro-cameras are small in size, they are the best choice for surveillance.

As trends may continue to grow in the future, PCB manufacturers will want to continue to develop micro-cameras and they are focusing on the more customizable micro-cameras to capture high-quality images and videos. The low light capabilities are also under development to meet the needs of surveillance.

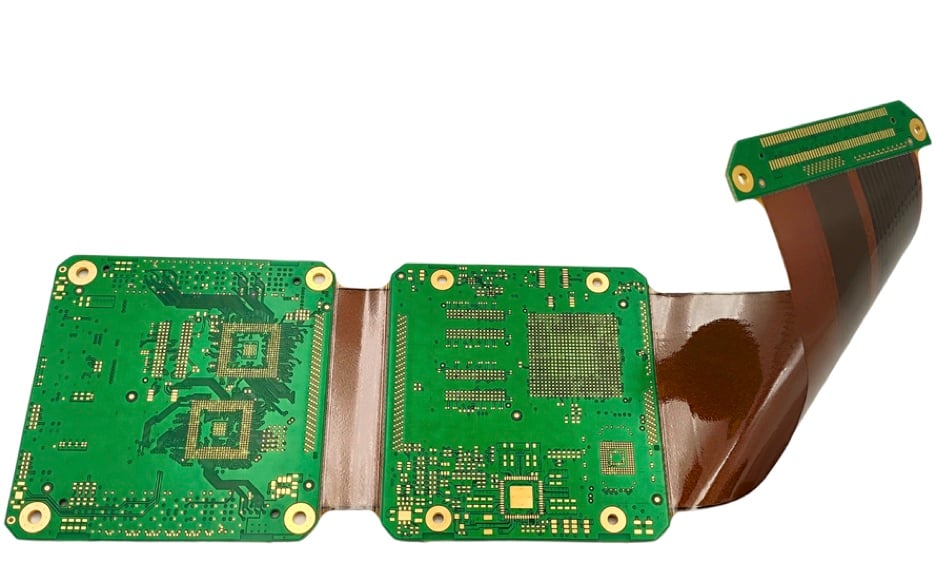

The Surge of Flex PCBs

Flexible PCB boards have almost the same qualities and performance compared with traditional printed circuit boards. The only difference is that they can bend and are twistable. Although the rate of shrinking the devices has been slowed down still they are growing into smaller and more complex structures. The manufacturers are in favor of making flexible devices that can accommodate unique designs and meet the requirements of the customers. Because PCBs are in demand and are the resources for flight engineers, and automakers, and are raw materials for medical products. Currently, the top priority of PCB manufacturers is to develop PCBs from rigid devices to flexible devices in PCB manufacturing.

However, one obstacle they are facing in production is the cost of making the flexible PCBs. Flexible PCBs require unique PCB manufacturing and assembly processes. Manufacturers are looking for a way to produce lightweight boards and are expecting a rise in the demand for flexible PCBs in 2024, which makes them more expensive than rigid PCB boards.

Flexible PCBs may have several advantages over rigid PCB boards. As the risks of damage during the assembly of the board are less in the flexible PCB boards, they can also be bent into a space-conserving shape which may reduce the size of an electronic device. Moreover, the designer can have multi-layer boards as they allow to have more layers than traditional PCB boards.

3D Printing PCBs in PCB manufacturing

Many industries including the PCB industry have been using 3D technology to print the designs of electronic devices. Predictably, 3D printing will continue to transform PCB manufacturing and design in the future. This technology allows you to manufacture the board of your desire which would have been impossible while using older techniques.

It uses CAD software, which is used to make 3-dimensional objects. In this step, a substrate is printed on board and other components are mounted on board with 3D technology. It uses different materials including plastics and liquids. The 3D printing is becoming more famous among manufacturers.

Popularity of SMT Technology

Manufacturers expect that SMT demand will continue to grow to manufacture the PCBs. In 2023 the share of the SMT was 60% in the market. This technology offers various advantages over the THT technology and other old technologies. This is considered to be the most efficient way to make PCBs because it has reduced component sizes and high density and improved electrical performance to direct the electrical signals during the PCB manufacturing and assembly process.

Conclusion

PCB manufacturing is changing as a result of emerging technology. To fulfill consumer demands and maintain competitiveness, manufacturers must adopt new procedures and technologies. Future opportunities for PCB manufacturing include boosting productivity, efficiency, and customization as well as integrating IoT, sustainability, and teamwork. Manufacturers who stay ahead of the curve and embrace developing technology may create brand-new, high-quality electrical devices that satisfy consumer demands and advance the sector.