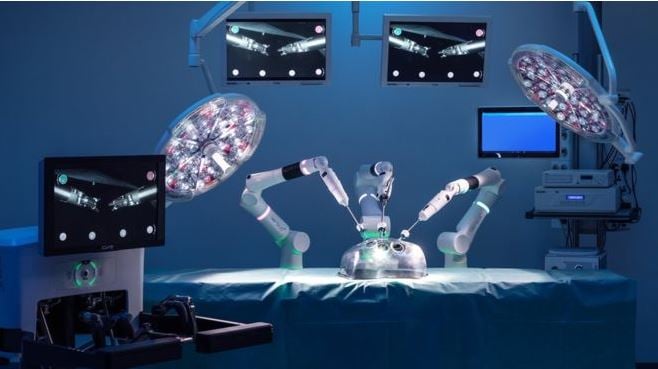

Robot arms are quickly becoming an integral part of the manufacturing industry. As technology advances, more industries are turning to robotic automation solutions for their assembly and production needs. Robot arms provide increased precision and efficiency in a fraction of the time it takes humans to do the same tasks. Such precise and efficient automation enables companies to save costs, increase output quality, and reduce wasted materials. This article will discuss how robot arms help enhance precision and efficiency in various industrial processes.

Implement automation

Automation plays a significant role in making the production process more efficient. Automated robot arms can be programmed to move and operate precisely, enabling them to perform complex tasks faster and more accurately than humans. By automating these processes, companies can reduce human labor costs and focus on higher-value activities.

Additionally, automated robots can be used for repetitive tasks that require precise movements, which humans may not be able to do as quickly or safely. For example, automated robots are often used in welding applications where they achieve better results and greater efficiency than manual welders.

Increasing accuracy

Robotic arms provide greater accuracy than manual labor regarding assembly and production tasks. Robot arms can easily be programmed to move within a tiny margin of error, ensuring that parts are assembled precisely and accurately. It is especially true for complex tasks such as 3D printing and laser cutting, where robot arms can perform the same operation thousands of times with perfect accuracy.

With increased precision, companies can significantly reduce waste, improve product quality, and reduce production costs. For example, robot arms can print out complex 3D parts more accurately and precisely than manual labor. Companies can produce higher-quality parts and components by integrating such precision into production.

Reducing cycle time

Robot arms can complete tasks faster than humans because they can perform multiple operations simultaneously. For example, a robotic arm is capable of loading materials into machines as well as assembling them at the same time. It allows for faster throughput and shorter cycle times, increasing efficiency.

Additionally, robot arms are not subject to fatigue or human error, so they can work continuously without taking breaks. It increases productivity and reduces costs due to less wasted time. It also reduces the need for human labor, allowing companies to focus their resources on higher-value activities.

Improving safety

Robotic arms provide a safer working environment than manual labor. Robot arms are designed to perform operations with extreme precision and accuracy that humans cannot achieve without the risk of injury. In addition, robotics automation eliminates the need for workers to be exposed to hazardous environments created by machines such as lathes and drills.

Robots can be programmed to detect any anomalies during operation, allowing them to immediately stop if something is wrong. They can also be programmed to detect and avoid obstacles in their path, reducing the risk of injury to workers.

Enhancing product quality

Robotic arms can improve product quality by performing tasks more accurately and precisely than humans. By using robotic automation, companies have complete control over the production process and can ensure that parts are assembled correctly and efficiently. It helps reduce material waste and ensures that products meet high-quality standards.

Robots can be trained to recognize defects in parts that may not be easily detectable by the human eye. It also helps reduce the needed rework, as robot arms can quickly identify errors and make corrections before products are shipped.

reducing costs

Robotic arms provide a cost-effective solution to automate complex processes. By automating various tasks with robot arms, companies can significantly reduce labor costs while increasing output quality and reducing wasted materials.

Additionally, robotic automation eliminates downtime associated with manual labor, allowing companies to produce more products in less time. Robot arms also require minimal maintenance compared to manual labor, resulting in lower operational costs. They are also more efficient than manual labor, as they can perform multiple tasks with greater accuracy and reliability.

Interesting Related Article: How Robots Are Contributing to Workplace Burnout

;Resize=(1200,627)&impolicy=perceptual&quality=mediumHigh&hash=be81604972a2811e0435980206cab6a690cd628f280617aa707ef11c18d3a1a1)

;Resize=(1200,627)&impolicy=perceptual&quality=medium&hash=129f6f74f51095b2b0c46904a22676eea41d5a0fc94fb8bd8f7716e9442a06c9)

;Resize=(1200,627)&impolicy=perceptual&quality=mediumHigh&hash=83d1e8286c356bdd72573519a1ec888ee5b7463066eb0faa712e65e5c3ede86f)

;Resize=(1200,627)&impolicy=perceptual&quality=medium&hash=d59189e8db6326232fe77a9d3f2c3aa5e9c5b5a2a8ad8f1f90fe0c38facadcae)